...and that leads us back to your Quite Excellent Photos... "Occam's Razor" bears out that "The Simplest Explanation of any problem is almost 99.99% Correct..." The Two locations that draw attention are:

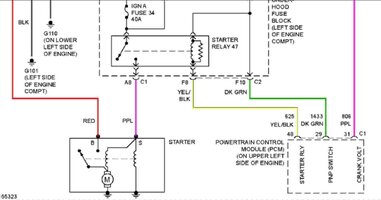

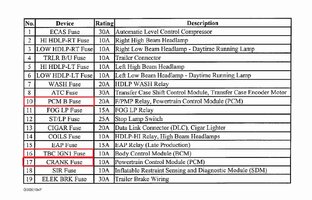

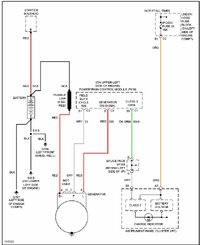

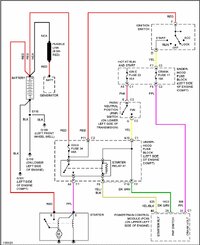

(1) Re-Visit the Cut Wires and Repairs for issue that the Butt-Connectors can hide since soldering wires is the only Best Practice to follow for power sensitive circuits that emanate from the Ignition-Starter Circuit.

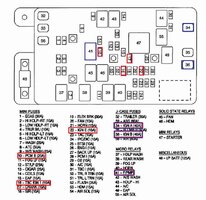

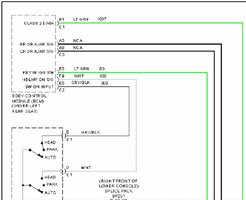

(2) Even without any signs of Rodent Predation...There are Under-Hood Nesting materials present in those photos showing that either Mice or Rats dragged that stuff up and around the Fuse Block, elevated above predators. Un-Bolting the Upper Fuse Block from the Lower Harness connectors and looking things over around there with a Bright Flashlight can often show locations of Chewed Through Wiring not visible in plain sight.

(1) Re-Visit the Cut Wires and Repairs for issue that the Butt-Connectors can hide since soldering wires is the only Best Practice to follow for power sensitive circuits that emanate from the Ignition-Starter Circuit.

(2) Even without any signs of Rodent Predation...There are Under-Hood Nesting materials present in those photos showing that either Mice or Rats dragged that stuff up and around the Fuse Block, elevated above predators. Un-Bolting the Upper Fuse Block from the Lower Harness connectors and looking things over around there with a Bright Flashlight can often show locations of Chewed Through Wiring not visible in plain sight.

Last edited:

)

)