If you own ANY Late Model GM Vehicles and you wind up getting a Whole RAT’S NEST of Trouble Codes…. The GM Diagnostic Tree is just a MORASS due to SO MANY MODULES BEING ON THE BUS NETWORKS.

BUT… Don’t Panic... and Don't Be Fooled… Divide your Electrical Issues IN HALF… First... Check for Power Losses on the B+ Battery Voltage Sides of Suspect Modules. Then… Check on the OTHER Side… Wherever You Have ANY GROUND CONNECTIONS.

In THIS Case involving 2019 Chevrolet Silverado Z71... GM's use of Braided Copper Bonding Straps in The Rust Belt States means that eventually… Cupric Oxide Corrosion WILL Set in and Dissolve the “Woven Fabric” of the Fine Copper Metal Mesh Fibers ...INTO A USELESS, POWDERY MUSH.

At the First Sign of having issues with the Power Electric Steering (Which can Draw up to 175 Amps when under Load) ...if the Power Steering Suddenly Drops Out and Stiffens... and you get a mess of other inexplicable Electrical Gremlins… STOP!

In situations where any of the Ground or Bonding Straps are COMPROMISED... Electricity WILL Seek to FIND GROUNDS by ANY Means POSSIBLE in the Vehicle... Hence the "Weird" Electrical Behaviors of other... possibly unrelated Modules Raising their Ugly Heads.

The Very First Thing To Do… Is REVIEW THIS VIDEO and Watch Eric “O” Show you Precisely Where to LOOK and What to LOOK For to perform a Basic Ground Strap R&R in as many locations as can be found that have turned GREEN… and Replace them ALL.

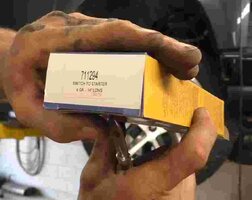

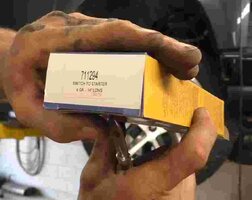

Here are some Before and After Screen Grabs from this Linked Video that will stress and emphasize What To Look For:

BUT… Don’t Panic... and Don't Be Fooled… Divide your Electrical Issues IN HALF… First... Check for Power Losses on the B+ Battery Voltage Sides of Suspect Modules. Then… Check on the OTHER Side… Wherever You Have ANY GROUND CONNECTIONS.

In THIS Case involving 2019 Chevrolet Silverado Z71... GM's use of Braided Copper Bonding Straps in The Rust Belt States means that eventually… Cupric Oxide Corrosion WILL Set in and Dissolve the “Woven Fabric” of the Fine Copper Metal Mesh Fibers ...INTO A USELESS, POWDERY MUSH.

At the First Sign of having issues with the Power Electric Steering (Which can Draw up to 175 Amps when under Load) ...if the Power Steering Suddenly Drops Out and Stiffens... and you get a mess of other inexplicable Electrical Gremlins… STOP!

In situations where any of the Ground or Bonding Straps are COMPROMISED... Electricity WILL Seek to FIND GROUNDS by ANY Means POSSIBLE in the Vehicle... Hence the "Weird" Electrical Behaviors of other... possibly unrelated Modules Raising their Ugly Heads.

The Very First Thing To Do… Is REVIEW THIS VIDEO and Watch Eric “O” Show you Precisely Where to LOOK and What to LOOK For to perform a Basic Ground Strap R&R in as many locations as can be found that have turned GREEN… and Replace them ALL.

Here are some Before and After Screen Grabs from this Linked Video that will stress and emphasize What To Look For:

Last edited:

. Flexibility, I'm sure -- but most of these never need to move, where they're installed.

. Flexibility, I'm sure -- but most of these never need to move, where they're installed.