- Apr 9, 2012

- 936

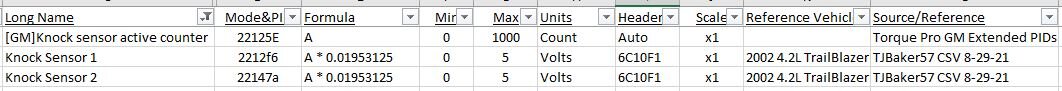

Hey guys! Added another GMT360 to the family, a 2008 TrailBlazer LT. Its been well kept up and maintained. There is one issue I'm having, the CEL came on for a knock sensor. The code is P0325 Knock Sensor 1 Circuit according to Torque.

I've got paperwork from the previous owner showing one of the knock sensors was replaced by the dealership a few months ago. It doesn't say which location it was, and I can't seem to pinpoint which sensor it is. I know there is one on the Left side of the engine block by the A/C compressor, and the other somewhere behind the block by the starter. Anyone dealt with replacing this one before?

I've got paperwork from the previous owner showing one of the knock sensors was replaced by the dealership a few months ago. It doesn't say which location it was, and I can't seem to pinpoint which sensor it is. I know there is one on the Left side of the engine block by the A/C compressor, and the other somewhere behind the block by the starter. Anyone dealt with replacing this one before?